Digital/analogue electronics

SERMA Ingénierie develops analogue and digital embedded electronic devices that meet the requirements of the most critical fields of application.

Power electronics/energy management

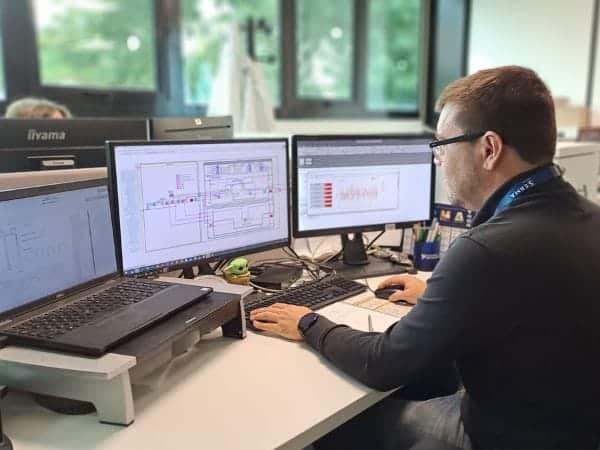

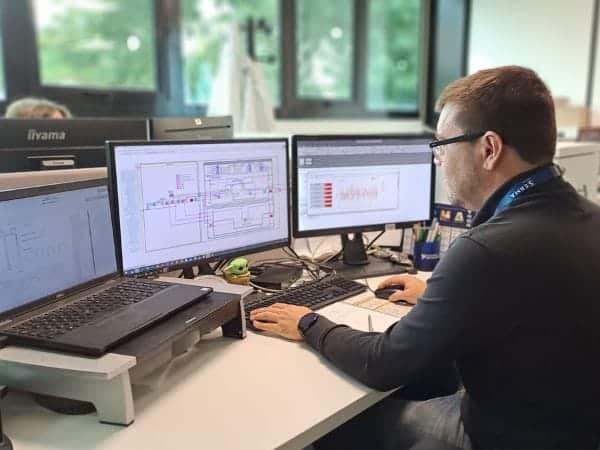

SERMA Ingénierie has several resources at its disposal to carry out these power electronics activities:

- Calculation and simulation tools for design, including Multiphysics simulations

- Mechanical and electronic CAD tools

- Test facilities dedicated to power, to characterize and validate the performance of equipment and systems implemented.

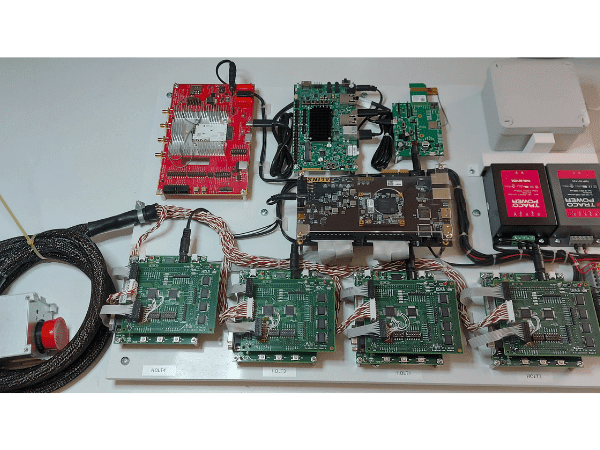

FPGA

SERMA Ingénierie employs over 60 experts with skilled knowledge of the FPGA design flows of the main brands: AMD, Microchip and Intel.

Our assets:

- Development in VHDL, Verilog, System Verilog and UVM languages

- FPGA experts with over 15 years’ experience (A/D and D/A converters, transceivers)

- Rapid set-up of in-situ and ex-situ platforms

- Project management by dedicated resources

- Quality monitoring processes and reviews by our technical peers

Mastered procedural baselines

- Aeronautics: DO254

- Rail: EN61508

- Space: ECSS REQUIREMENT

Artificial Intelligence

Artificial Intelligence is a strategic sector for the company. Today, SERMA Ingénierie works with latest-generation FPGAs to embed AI in image processing.

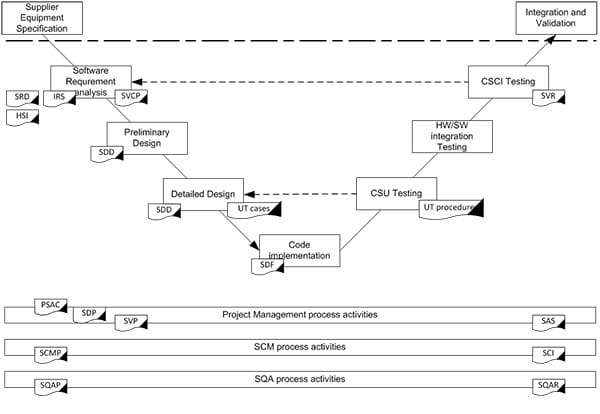

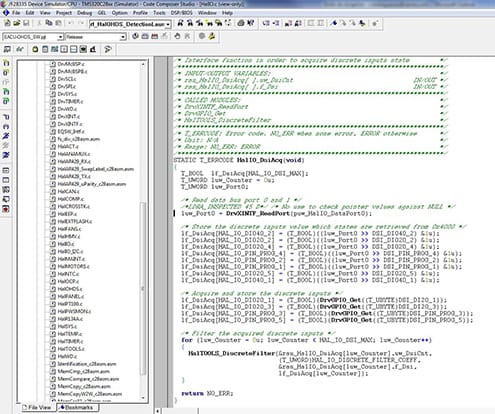

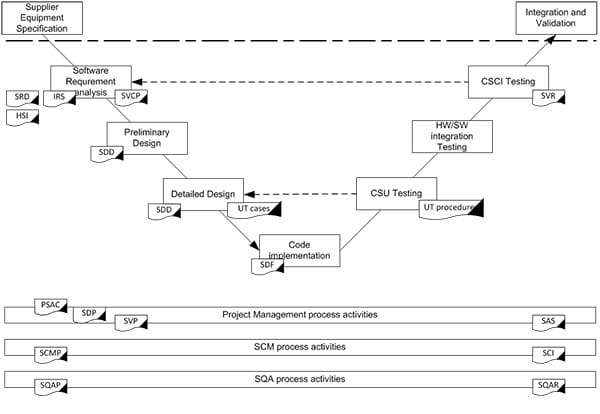

Embedded software

SERMA supports you right from the analysis of the specification.

Proactive and perfectly positioned to advise you about architecture, choice of OS, real-time kernels and communication protocols, our SERMA engineers are very familiar with development techniques such as DO178. They develop, document and qualify an extremely wide variety of software programmes and cover the following areas:

- Compliance with DO178

- Drivers, Firmwave

- Application software (algorithms, control laws)

- Boot loader

- HMI, Labview

- Board Support Package

- C, C++, ADA

- Certification

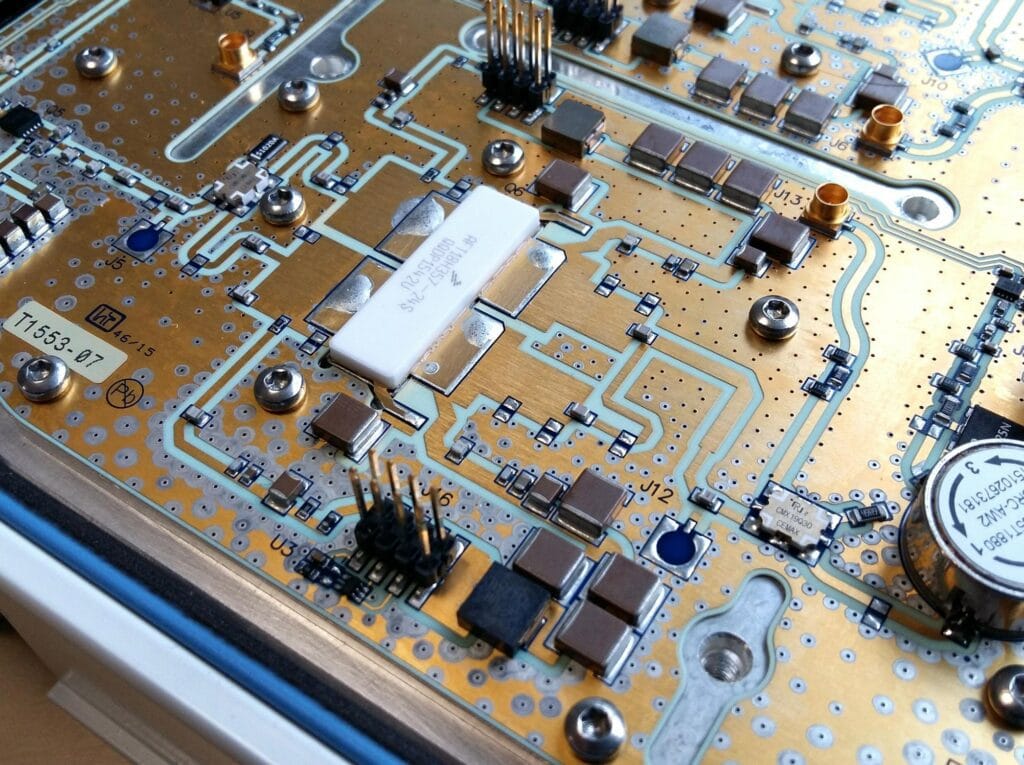

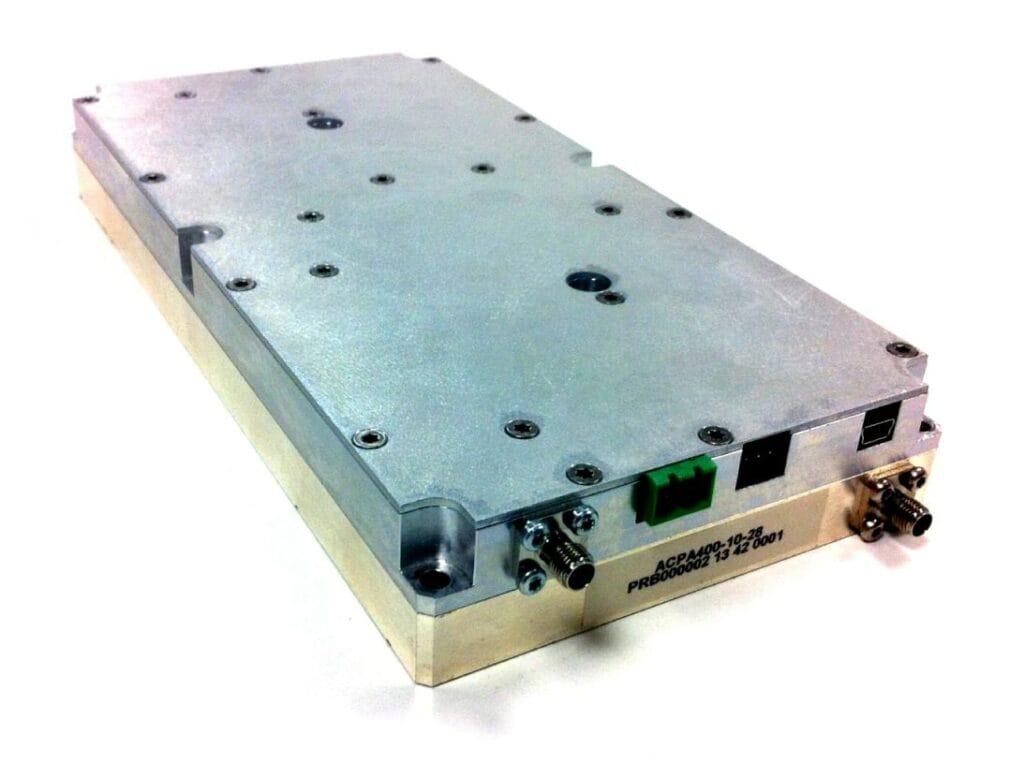

RF Technology

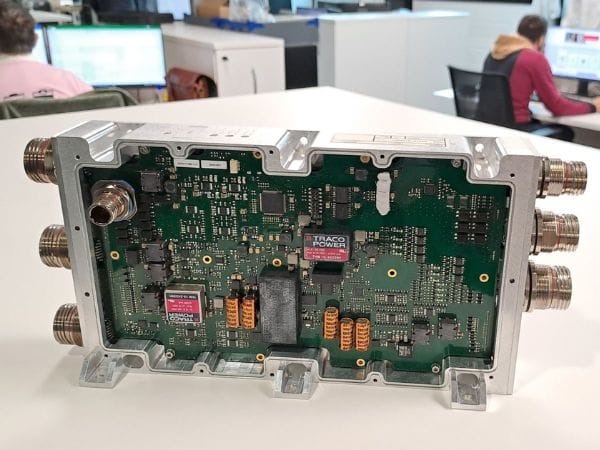

SERMA Ingénierie is responsible for the development and manufacturing of high-performance, complete systems and sub-systems for wireless telecommunication infrastructures.

Full Transmitter/Receiver chains

SERMA develops full transmission and reception chains ranging from 100MHz to 6GHz.

Based on platforms that combine both digital and analogue devices (FPGA, DAC, ADC, Transceiver/Receiver), these chains are able to:

- Generate and receive signals

- Convert up and down frequencies (mixers, LO, etc.).

- Perform modulation and demodulation of signals

- Highly sensitive, thanks to LNAs with a low noise factor

These chains are also agile in terms of frequency: SDR (Software Defined Radio).

RF power amplifiers

SERMA develops RF power amplifiers ranging from several milliwatts to several hundred Watts.

They enable us to achieve extremely accurate results, via skilled handling of:

- The various types of transistor technologies: LDMOS, GaN, etc.

- Advanced amplifier architecture techniques: Class AB, Doherty Amplifier, Asymmetric Doherty Amplifier, etc.

These amplifiers also enable us to achieve high levels of linearity thanks to the use of error correction technologies:

- Analogue-corrected amplifiers (Feedforward, Cartesian Feedback)

- Digitally-corrected amplifiers (Digital Pre-Distortion, CFR)

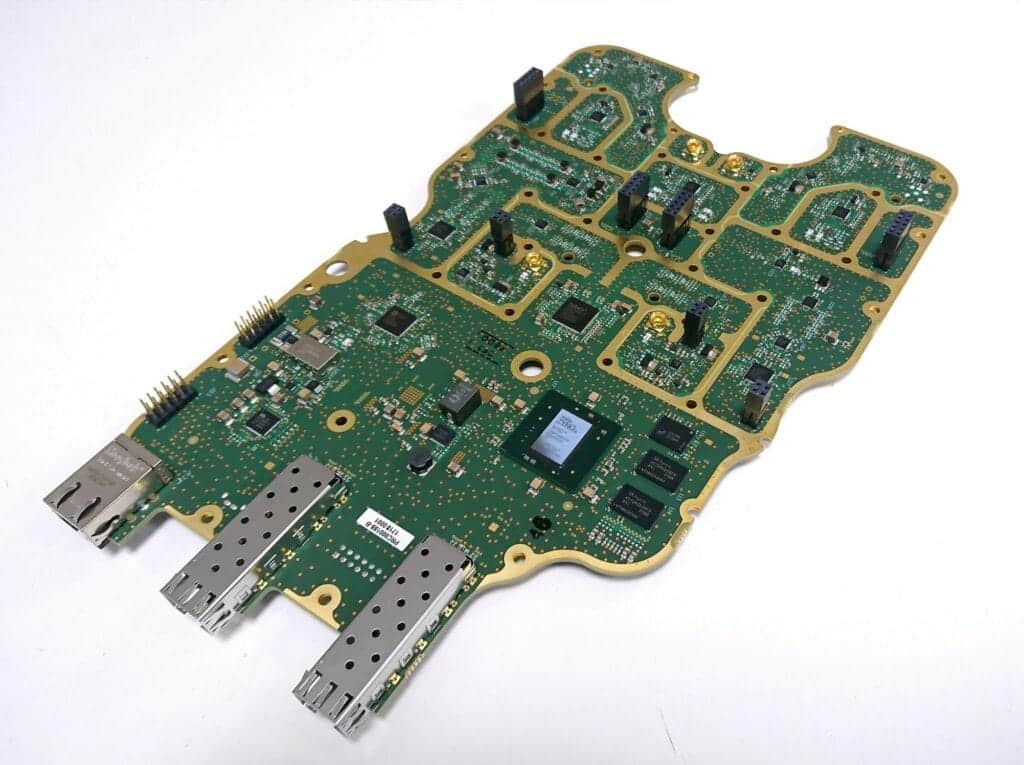

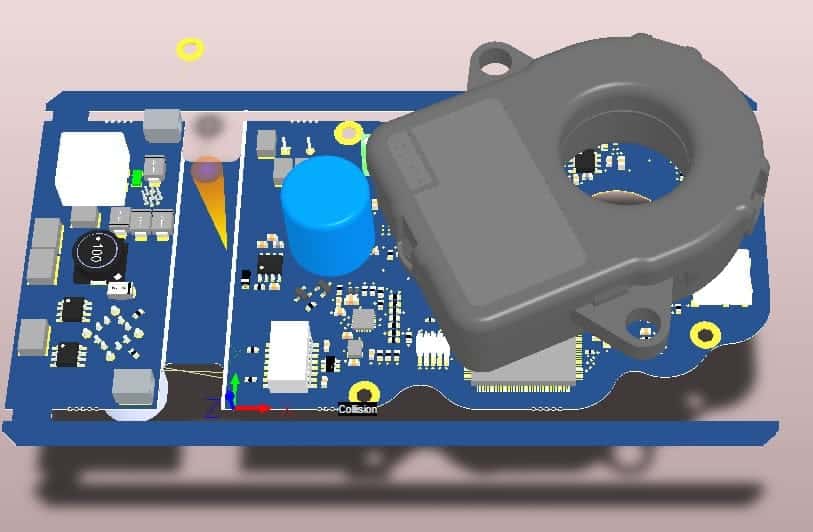

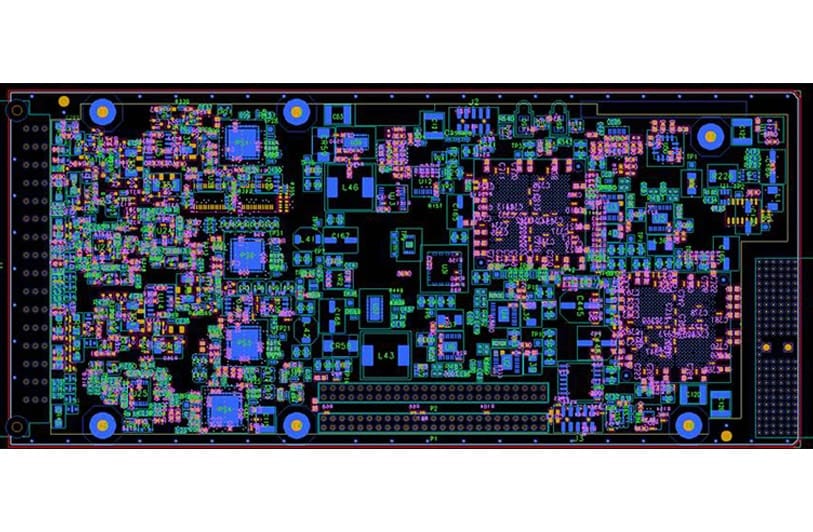

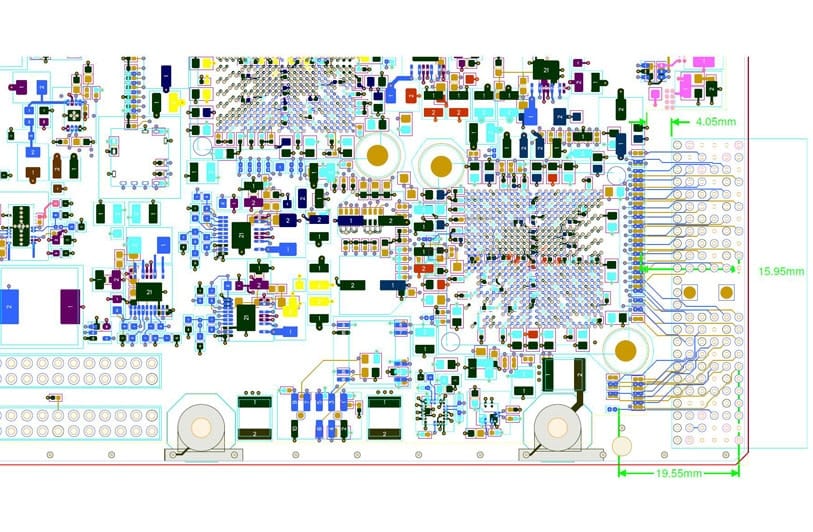

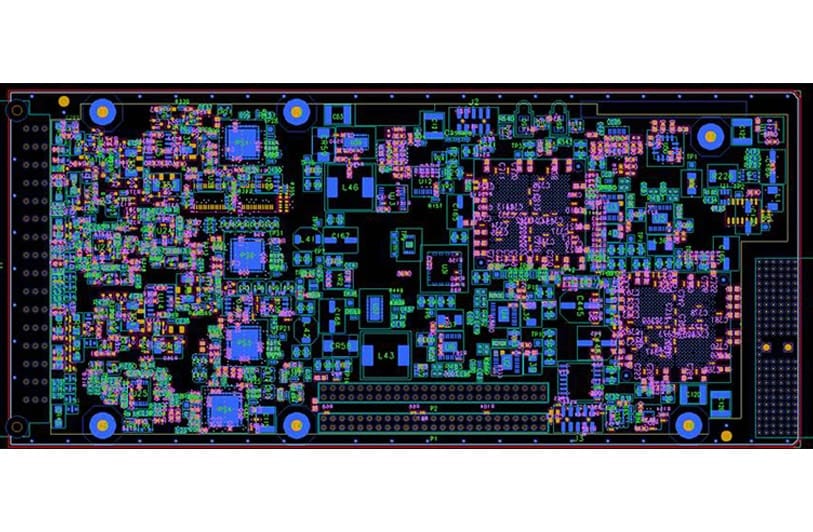

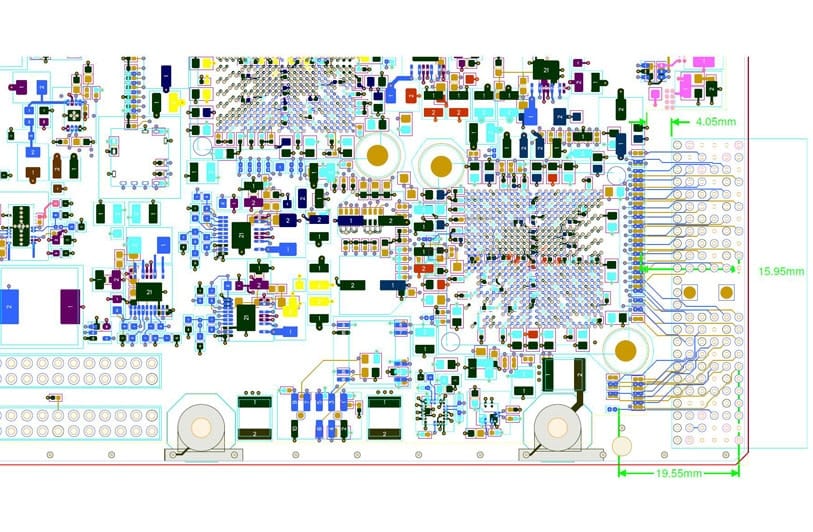

CAD

SERMA Ingénierie has an electronics CAD department that masters the 4 key stages of modelling of components, schematic design, placement and routing and file generation.

Our CAD process for electronics offers:

- Expertise in printed circuit board technologies: Flex, multilayer, heat sink, SMI.

- Mastery of methodologies and compliance with standards: IPC 2221, IPC 2223, IPC 7351, NF 93713.

- Integration of “signal integrity” aspects: analysis during routing, post-routing analysis.

- Incorporation of industrialization constraints: Sectors (health care, automotive, aeronautics, rail, defense), EMS (reproduction of PCBs, assembly technologies, in-situ testing), EMC, manufacturability, in-house(capitalization and feedback).

- Taking charge of prototype production

Tools used

Our expert knowledge of CAD using tools such as Cadence (ORCAD ®, Allegro® PCB Design HDL, Allegro® PCB Performance, Allegro® PCB Routing), Mentor PADS®, Mentor Board Station ® (Design Architect), Mentor Expedition® (DxDesigner ExpPCB, Expedition Pinnacle, Library Manager, Fablink XE Pro) and ALTIUM® means we are able to produce complex circuits based primarily on:

- Stack-up: High-density multi-layers with μBGA on both sides

- Pitch: Fine-pitch BGAs of 0.8mm, 0.5mm, 0.4mm (HDI)

- Mixed-component assemblies and CMS (PTH/SMD)

- Holder: Epoxy, Kapton, Rogers, Flex, etc.

- Via: buried vias, laser vias, short-diameter through-holes

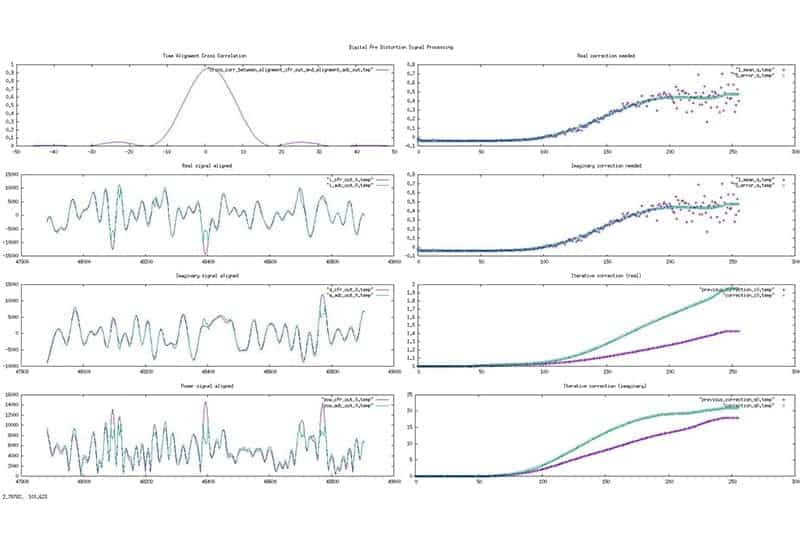

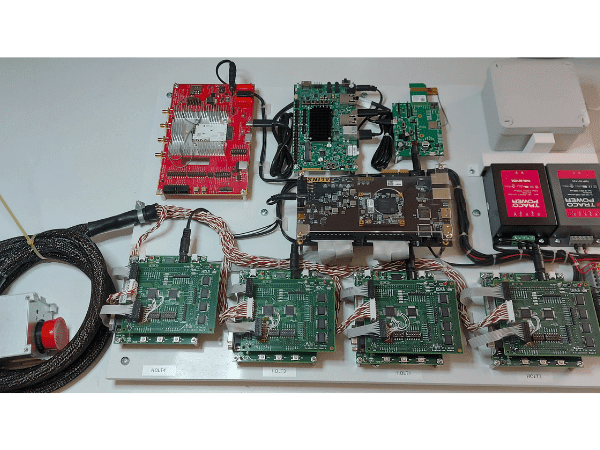

Signal processing

SERMA Ingénierie provides hardware and software development services for digital signal processing platforms.

Based on components such as FPGA, DSP, DAC, ADC, we provide you with assistance for these platforms focused on the development and implementation of:

High-speed protocols: CPRI, JESD, GbE/10GbE, PCIe

Real-time OSs: open-source or licensed

We are also fully skilled in the development of real-time signal processing algorithms, enabling for example:

- Digital Pre-Distortion (DPD) or Crest Factor Reduction (CFR) for RF amplifiers

- Signal generation and digitisation

- Modulation and demodulation of complex signals (standard or proprietary)

- Various types of digital filtering

- Automatic Gain Control (AGC) for transmitters

- Analysis, correlation and processing of digital signals

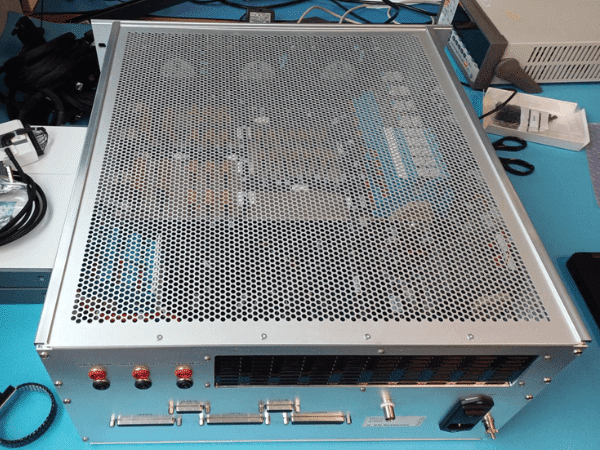

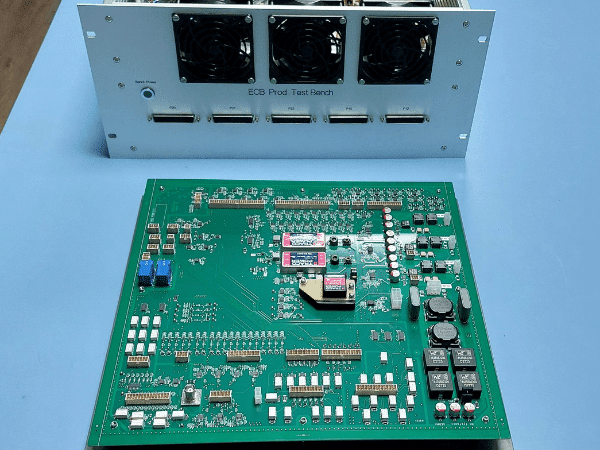

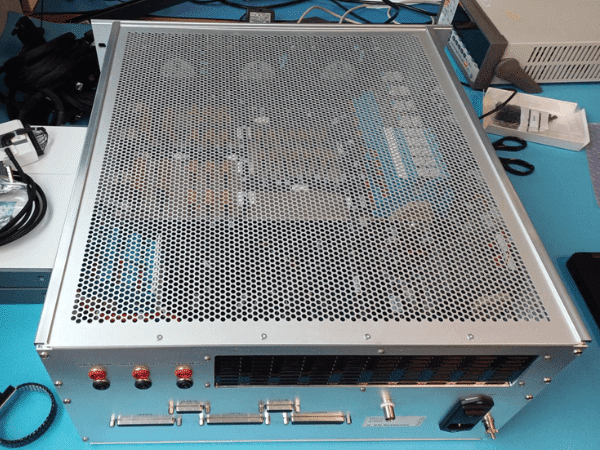

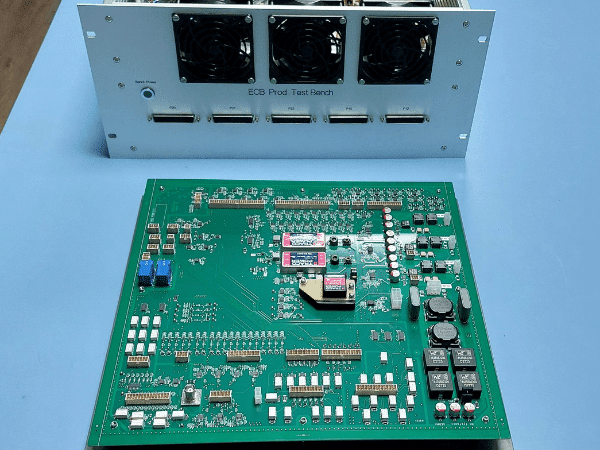

Test

SERMA Ingénierie has built up expertise in the production of test means mainly associated with the products (boards, equipment items) developed by our customers.

Our experts design systems for testing the design, integration, production and repair of embedded equipment items.

Types of test benches provided:

- Analogue / digital

- Power

- RF

SERMA Ingénierie has acquired expertise in the construction of test facilities (more than 100 test benches deployed at our sites and by our customers)…

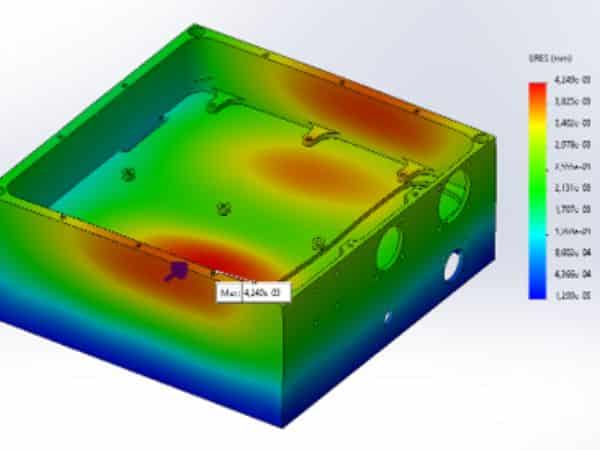

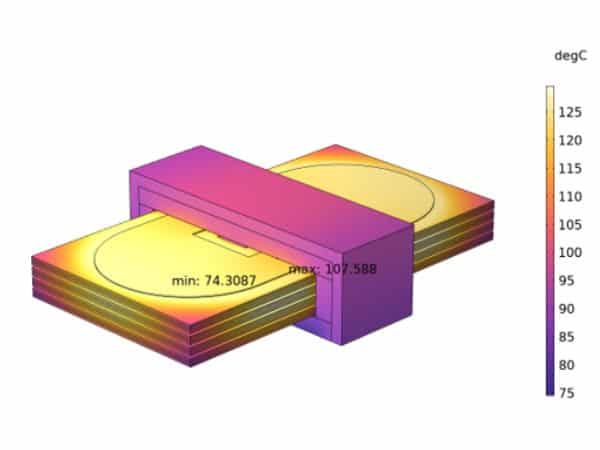

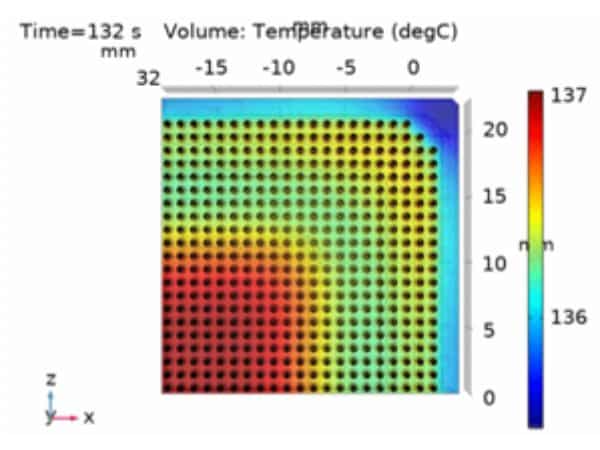

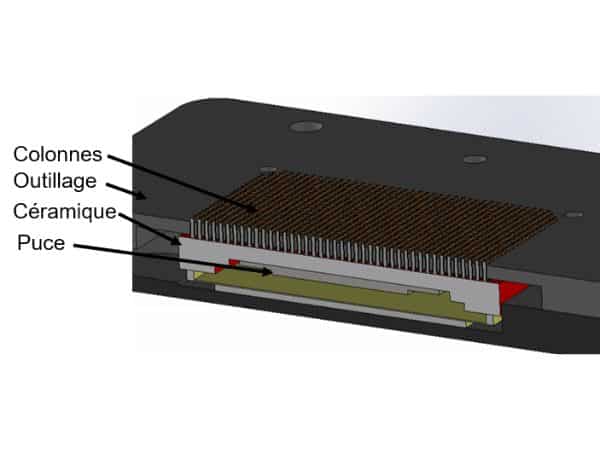

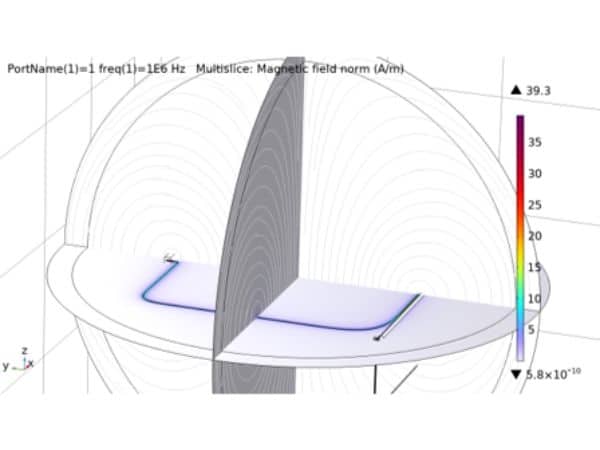

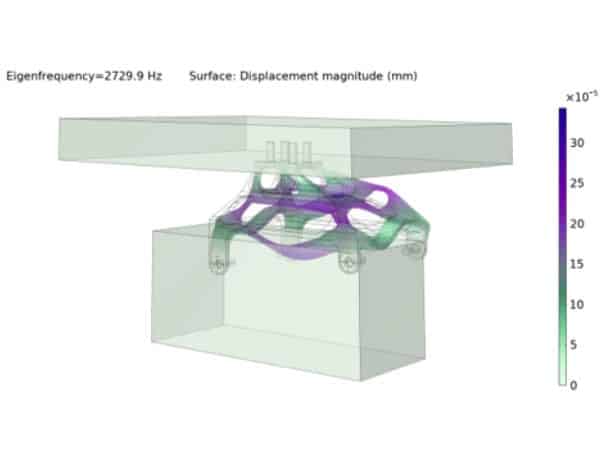

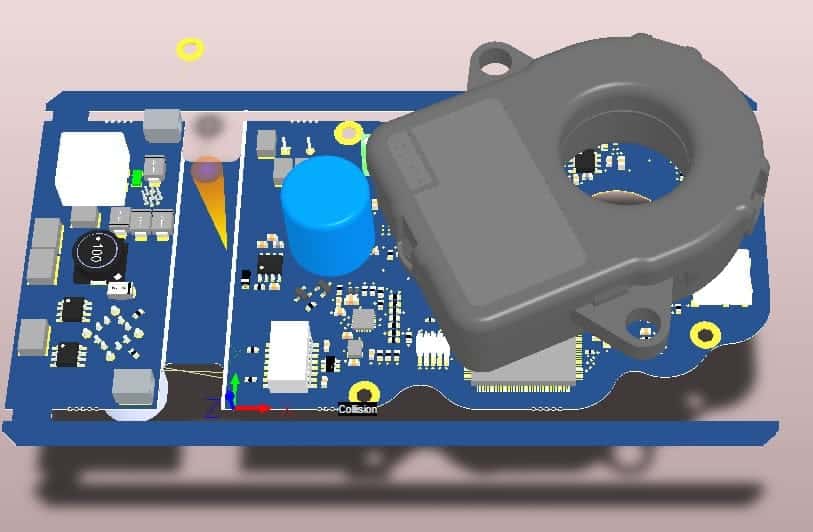

Multiphysic simulation

SERMA Ingénierie offers advanced multiphysics simulation solutions to optimize the design and development of complex systems.

SERMA excels in the analysis and modeling of multiphysical couplings, enabling us to solve development problems such as thermal distribution, humidity and vibration. These simulations offer significant gains in terms of product reliability and manufacturing process optimization.

Fields of application

- Thermal

- CEM

- Mechanical

What are the advantages?

- Faithful reproduction of equipment behavior

- Derisking during development

- Reduced development time

- Cost reduction

SERMA’s rigorous, innovative approach guarantees its customers reliable simulations that meet the most stringent requirements.